SHAW HAWKEYE HUGHES

Cal Poly Bike Builders

Cal Poly Bike Builders is a student-run Mechanical Engineering club at Cal Poly SLO. Any student with an idea for a bicycle can design and ultimately fabricate it with our guidance (and our sweet Anvil frame jigs). For a few years, we built frames and components as a club to exhibit at the North American Handmade Bike Show (NAHBS). Club projects are a great way for us to pass on our knowledge to newer members while tackling some more involved projects.

I have been an officer of the club since my second year at Poly, and I was president for a couple of years. I've included a few of my favorite club projects below:

Click here to go back to my portfolio.

NAHBS 2019 | Steel Downhill Bike

As NAHBS lead for the 2018-19 year, I oversaw the design and construction of a chromoly downhill bike. Our goal was to make as many parts of the bike as possible, so everyone had the opportunity to head up a "subsystem": pedals, stem, bashguard, chainring, brakes, and even a bell. I designed the frame, did all of the welding, and machined the lower link, shock mount, dropouts, derailleur hanger, and pivot hardware. I also organized multiple design reviews attended by professors and other clubs.

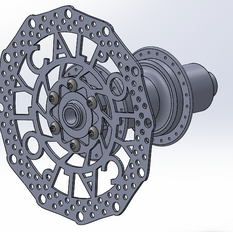

NAHBS 2018 | Hubs

As a second year, I took on the design and manufacture of mountain bike hubs. I borrowed the ratcheting mechanism another hub, so this wasn't a terribly complicated part. However, I was still a fairly novice machinist and CAD designer, so I learned a lot making these hubs.

NAHBS 2018 | Carbon Road Bike

This bike was our club's first foray into carbon fiber. A senior member of the club designed the frame, and we all worked together to fabricate the bike.

We made the entire frame in house: the lugs were made with a trapped rubber process, and the tubes were laid up around aluminum mandrels and wrapped with polyester shrink tape. We bonded the tubes to the lugs with DP420 adhesive and gave the frame a gold flake paint job.

NAHBS 2017 | Headtube Badge

My first year in the club, I was an inexperienced freshman who had almost no experience with metalworking. Although it is hardly a critical component of a bike, making a head tube badge was the perfect first project, and I jumped in headfirst.

I gained inspiration from Jen Green, who makes gorgeous head tube badges for Black Sheep Bikes. My mom, a jeweler by trade, helped me design the badge. I hand cut and filed each piece of nickel, brass, and copper and joined them with silver solder.